The remembered fever of voluminous and heavy Hi-Fi equipment seems to

be back. The suspected reason is its special quality of electronic design and high

quality materials, in contrast to the present equipment where plastic and other

similar materials are not as resistant to the test of time.

The golden age of Hi-Fi equipment is particularly remembered

in the 70's and 80's. Automation in electronic design took its first steps and

designers and engineers only had the most advanced techniques for the time to

develop and design circuits and electronic components, especially in the 70's

and early 80's.

The design and testing of these equipment was done with

special compliance and care from circuit calculations to the manufacture of the

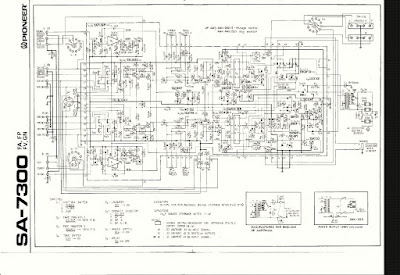

PCB and the schematic diagram, amount of those schematic diagrams made by

professional draftsmen without the present computer technology and automation.

The audio

companies in past times had their own drafting department (professional draftsmen

were worth only compass, sets square, insoles and molds-for in physical schematics

of their respective components, perfect delineation, faultless lace of line and

drawing. *¨In the electrical industry, a schematic diagram is often used to

describe the design of equipment. Schematic diagrams are often used for the

maintenance and repair of electronic and electro mechanical systems.[1] Original

schematics were done by hand, using standardized templates or pre-printed

adhesive symbols, but today Electrical CAD software is often used.In electronic

design automation, until the 1980s schematics were virtually the only formal

representation for circuits.¨ http://.en.wikipedia.org/wiki/Schematic

The

designers were required to different quality standards such as DIN, IHF, etc.

and resulted in the production of equipment with very outstanding features and

arrogance sound quality |

| Amount of schematic diagrams made by professional draftsmen without the present computer technology and automation. |

The concept of "Hi Fi" (High Fidelity) begins to

come into play when the quality of the audio system reaches or exceeds a

certain level.

This level of quality is determined by several factors that

basically respond to the idea that in our ear comes a sound as similar as

possible to the one that was generated at source. This means that a Hi-Fi chain

would try to make the buyer of a classical music record sitting comfortably at

home feel the same auditory sensations as if they were in the best location in

the concert hall: to recognize the sound of each instrument, to situate it

spatially, to listen to the slightest tinkling, to appreciate the differences

in level between a " Pianissimo " and a " Fortissimo "

etc.

The main peculiarity of Hi-Fi equipment of other times and

that makes them precisely attractive is its robust construction and high

quality design circuits that with much possibility surpass the test of time.

Another property that makes them striking is their complete compatibility

between brands, models and years in which they were manufactured, which offers

a total flexibility when wanting to make a high fidelity audio chain according

to the tastes and preferences of each person, (many take passion collecting

large number of components to show them).

Many people are inhibited and unsure of risking time and

money in buying appliances that have many years, however, that should not be

analyzed that way. A lot of repairing electronics technicians (I included) have bought Hi-Fi

equipment many times, and the important thing is to test all the functions and

if you get something that does not work, just do not buy that equipment, that's

the rule, so you do not risk in buying something that is not in good condition.

Fortunately, Hi-Fi equipment abounds in good condition and better still in

excellent condition even if they are many years old, keep in mind that the

electronic design of those old Hi-Fi equipment is truly outstanding and

reliable.